Matching Primary And Secondary Mining Mills

.jpg)

Beyond SAG milling – The future of grinding AusIMM

2024年8月27日 Autogenous milling (primary and secondary milling) [eg Aitik and Forrestania]; single stage autogenous milling [eg Olympic Dam and Kambalda]; and autogenous primary 2023年12月11日 primary semiautogenous (SAG) mill with a trommel screen, a pebble crusher and a dedicated cyclone cluster Crushed pebbles and primary cyclone underflow streams Merits of Optimised Milling Configuration on Process2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material 2023年1月4日 To aid in particle size reduction, grinding media in the form of balls, made of either cast iron or steel are used in tumbling mills (Scieszka et al, 1991) Commonly, two Selection of Grinding Media for Use in the Gold 2024年6月1日 SAG mills provide the modern mining industry with workhorses able to manage most high throughput grinding tasks Photo: FLSmidth predictive control (MPC), enhances THE FUTURE OF SAG MILLS Ausenco2024年9月24日 These methods and strategies will focus specifically on the two major stirred mill machine types; namely, gravityinduced (VERTIMILLTM grinding mill and NippionEirich tower TECHNOLOGY SELECTION OF STIRRED MILLS FOR

.jpg)

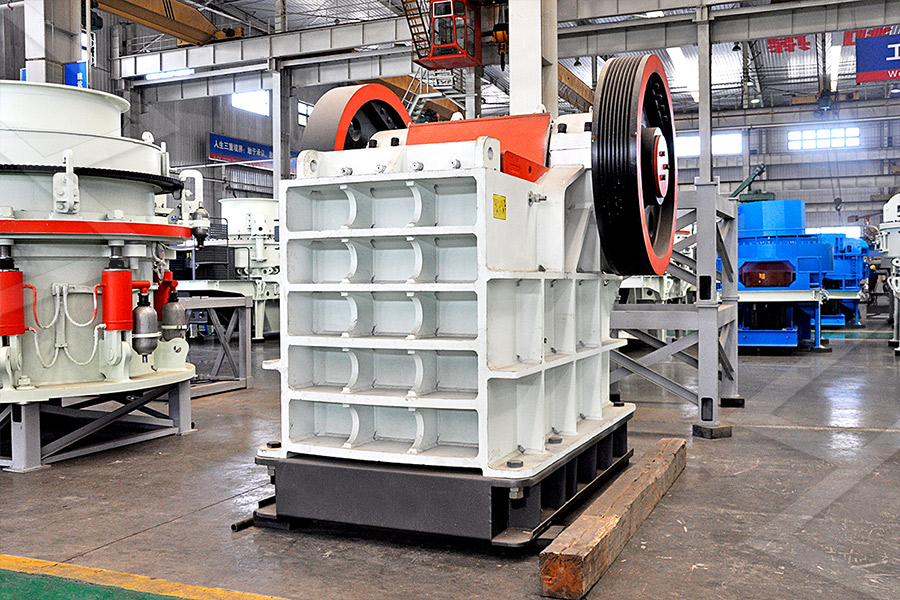

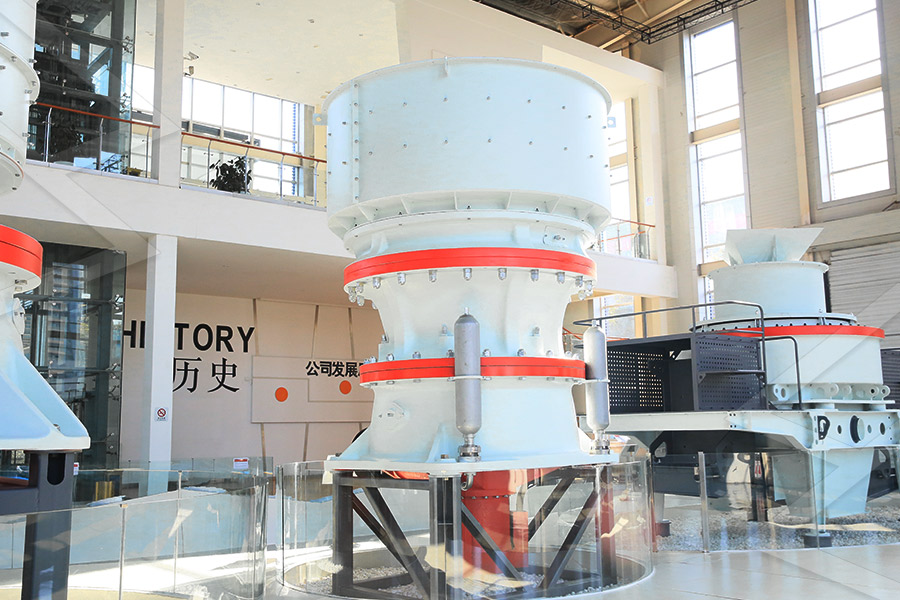

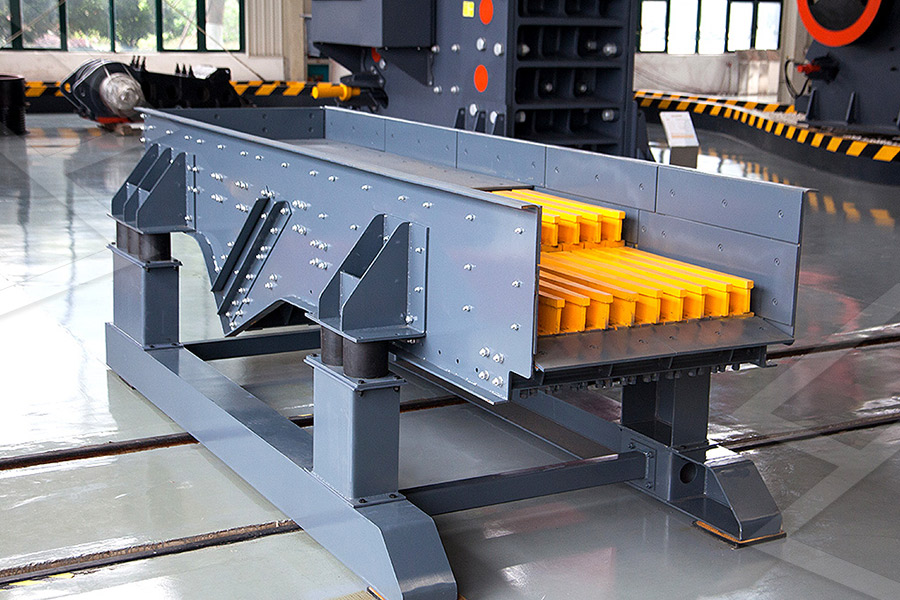

Rubber Mill Liner Andes Mining

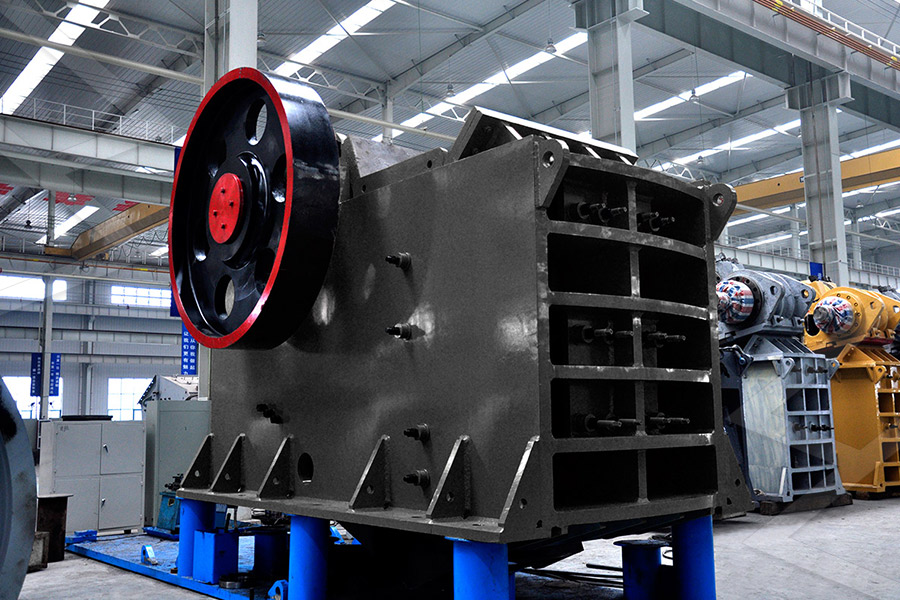

Andes Mining® is a leading in design, manufacture and supply of mill and crusher liners for primary, secondary, and tertiary grinding mills applications in the global mineral processing industry We offer our customers complete wear liner 2025年5月12日 Mining mills play a critical role in the mineral processing industry, serving as the primary equipment for reducing the size of ore particles It provides an overview of the latest advancements in mining mill technology, Advancements in Mining Mill Technology: Ball mills as well as rod mills are widely used in the mining industry on account of their simplicity Ball mills in particular play an important role in secondary grinding of ores to final particle sizes smaller than 100 µm The market leader Metso Trends in der Minenindustrie Mineral Processing2019年12月12日 160 mm and 170 mm for the primary and secondary mills respectively The primary mill lifter heighttoangle (H2A, defined as the height from the base of the lifter to a Milling circuit optimization study for Kroondal no 1 2023年2月28日 Primary vs Secondary Crushers: While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles into the desired Primary Crusher vs Secondary Crusher: sbm matching crushing system of the millCrushing Plant Flowsheet amp; Design Layout In the crushing section,the ore as it comes from the mine is broken down dry to a size suitable for the sbm matching crushing system of the millmd

Trends in der Minenindustrie Mineral Processing

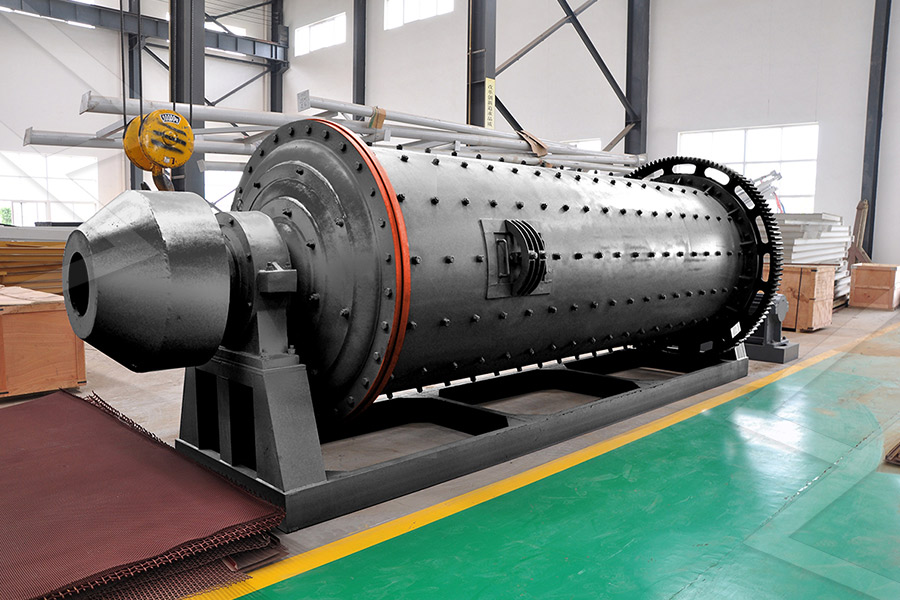

Ball mills as well as rod mills are widely used in the mining industry on account of their simplicity Ball mills in particular play an important role in secondary grinding of ores to final particle sizes 2024年9月24日 TECHNOLOGY SELECTION OF STIRRED MILLS FOR ENERGY EFFICIENCY IN PRIMARY AND REGRINDING APPLICATIONS FOR THE PLATINUM INDUSTRY C TECHNOLOGY SELECTION OF STIRRED MILLS FOR 2024年10月31日 Rod mills are typically used in the primary and secondary milling processes in various industries, particularly in the mining and metalworking sectors 02 Key Features of Rod A Comprehensive Guide to Rod Mill Applications Mining 2023年2月28日 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes Each stage uses The Complete Guide to Primary Crushing, Secondary Mineral milling, a pivotal process in the realm of mineral processing, is all about breaking down ores into finer particles This transformative process commences with primary and secondary Mineral Milling and Processing Atritor2020年1月21日 160 mm and 170 mm for the primary and secondary mills respectively The primary mill lifter heighttoangle (H2A, defined as the height from the base of the lifter to a Milling circuit optimization study for Kroondal no 1

Beyond SAG milling – The future of grinding AusIMM

2024年8月27日 Autogenous milling (primary and secondary milling) [eg Aitik and Forrestania]; single stage autogenous milling [eg Olympic Dam and Kambalda]; and autogenous primary 2020年6月1日 In the mining industry, the ideal target particle size for comminution is the liberation size, the size around which the valuable mineral can be effectively separated from Stirred media mills in the mining industry: Material 2023年12月11日 added flexibility of feeding both mills simultaneously with fresh feed or feeding the ball mill exclusively, depending on the quality of the fresh ore or downtime on the SAG mill Merits of Optimised Milling Configuration on ProcessCrusher For Primary Secondary And Tetiary Process Crusher Crusher For Primary Secondary And Tetiary 27 Views The liming is the professional mining equipments Crusher Primary Secondary Crusher Mills, Cone Crusher, 2024年11月4日 Secondary crushers Metso Nordberg MPIOOO Power 750 Kw Scalping screens 2 x double 73 m HPGR stockpile Live cap m' 23m x power 56 SAG mill 122m x power 20 A review of operating data over 50 years of secondary 2024年11月4日 Paper presented by Rajiv Chandramohan at the AusIMM Mill Operators Conference in Perth, Australia in October 2024 Abstract Since their first application in the late A review of operating data over 50 years of secondary

Milling circuit optimization study for Kroondal no 1

Figure 3 shows the current lifters installed in the primary and secondary mill The lifters are 210 mm wide, with heights of 160 mm and 170 mm for the primary and secondary mills 2023年10月10日 Primary activities Primary activities are directly dependent on the environment as these refer to utilisation of earth’s resources such as land, water, vegetation, building Sectors of Economy: Primary, Secondary, Tertiary, Quaternary 2024年10月11日 In the aggregate, mining, and construction industries, crushing plays a pivotal role in transforming raw materials into the desired product The use of crusher ensures that Primary and Secondary Trio Crusher miningasia2025年2月6日 Secondary mineral deposits present a significant opportunity for economic advancement within the mining sector By leveraging materials that were previously discarded Unlocking Value in Secondary Mineral Deposits – MiningWorldNumerous posters and presentations were shown, in addition to twentyfive papers presented by wellknown representatives of commercial companies and research institutions The prime focuses of the 2010 conference included, Primary and secondary minerals preparation2018年3月11日 Transverse longitudinal stoping, also commonly referred to as primary secondary sequence mining is useful in cases where the rock quality of the hanging wall limits the length of the open mining span Bighole stoping is Types of Mining Methods Sell Side Handbook

How Mine Milling Section Report PDF Mill

2017年12月13日 How Mine Milling Section Report Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The document summarizes the milling circuits and major equipment at Metallon 2015年4月9日 Suitability of different mills for grinding operations Some of the characteristics and requirements to be considered when selecting a grinding mill are given below Material Grinding Mills and Their Types IspatGuru2025年5月12日 Mining mills play a critical role in the mineral processing industry, serving as the primary equipment for reducing the size of ore particles Cylinder: The primary component Advancements in Mining Mill Technology: Efficiency, 2023年2月10日 Primary crushers and secondary crushers are used in the mining and quarrying industry to crush rocks and aggregate, respectively A primary crusher is a heavyduty what is a primary and secondary crusher? LinkedIn2023年2月28日 Hammer mills: These crushers use highspeed rotating hammers to crush the material They are ideal for crushing soft to mediumhard materials such as coal, limestone, Primary vs Secondary Crushers: Understanding the Mineral ore comminution is generally a feed preparation step for subsequent processing stages Grinding, the fine product phase of comminution, requires a large capital investment and Rod and Ball Mills OneMine

Autogenous and Semiautogenous Grinding Circuits

He has a BASc in Mining Mineral Process Engineering (1992) from the University of British Columbia in Vancouver, Canada Past editor of the Procemin 2012 2013 conferences 2024年2月6日 This middle step is super important if you need specific sizes for things like building projects, pulling out minerals, or more detailed industrial processing Jaw crushers in Understanding Types of Jaw Crusher: A Comprehensive 2019年12月12日 160 mm and 170 mm for the primary and secondary mills respectively The primary mill lifter heighttoangle (H2A, defined as the height from the base of the lifter to a Milling circuit optimization study for Kroondal no 1 2023年2月28日 Primary vs Secondary Crushers: While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles into the desired Primary Crusher vs Secondary Crusher: sbm matching crushing system of the millCrushing Plant Flowsheet amp; Design Layout In the crushing section,the ore as it comes from the mine is broken down dry to a size suitable for the sbm matching crushing system of the millmdBall mills as well as rod mills are widely used in the mining industry on account of their simplicity Ball mills in particular play an important role in secondary grinding of ores to final particle sizes Trends in der Minenindustrie Mineral Processing

TECHNOLOGY SELECTION OF STIRRED MILLS FOR

2024年9月24日 TECHNOLOGY SELECTION OF STIRRED MILLS FOR ENERGY EFFICIENCY IN PRIMARY AND REGRINDING APPLICATIONS FOR THE PLATINUM INDUSTRY C 2024年10月31日 Rod mills are typically used in the primary and secondary milling processes in various industries, particularly in the mining and metalworking sectors 02 Key Features of Rod A Comprehensive Guide to Rod Mill Applications Mining 2023年2月28日 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes Each stage uses The Complete Guide to Primary Crushing, Secondary Mineral milling, a pivotal process in the realm of mineral processing, is all about breaking down ores into finer particles This transformative process commences with primary and secondary Mineral Milling and Processing Atritor2020年1月21日 160 mm and 170 mm for the primary and secondary mills respectively The primary mill lifter heighttoangle (H2A, defined as the height from the base of the lifter to a Milling circuit optimization study for Kroondal no 1 2024年8月27日 Autogenous milling (primary and secondary milling) [eg Aitik and Forrestania]; single stage autogenous milling [eg Olympic Dam and Kambalda]; and autogenous primary Beyond SAG milling – The future of grinding AusIMM

Merits of Optimised Milling Configuration on Process

2023年12月11日 primary semiautogenous (SAG) mill with a trommel screen, a pebble crusher and a dedicated cyclone cluster Crushed pebbles and primary cyclone underflow streams 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material 2023年1月4日 To aid in particle size reduction, grinding media in the form of balls, made of either cast iron or steel are used in tumbling mills (Scieszka et al, 1991) Commonly, two Selection of Grinding Media for Use in the Gold 2024年6月1日 SAG mills provide the modern mining industry with workhorses able to manage most high throughput grinding tasks Photo: FLSmidth predictive control (MPC), enhances THE FUTURE OF SAG MILLS Ausenco2024年9月24日 These methods and strategies will focus specifically on the two major stirred mill machine types; namely, gravityinduced (VERTIMILLTM grinding mill and NippionEirich tower TECHNOLOGY SELECTION OF STIRRED MILLS FOR Andes Mining® is a leading in design, manufacture and supply of mill and crusher liners for primary, secondary, and tertiary grinding mills applications in the global mineral processing industry We offer our customers complete wear liner Rubber Mill Liner Andes Mining

.jpg)

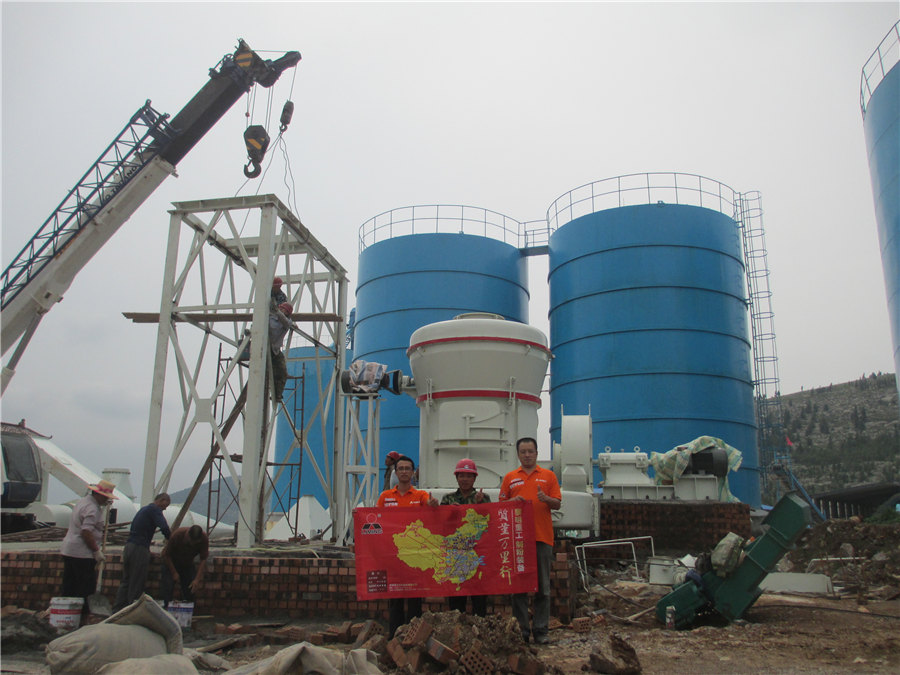

Advancements in Mining Mill Technology:

2025年5月12日 Mining mills play a critical role in the mineral processing industry, serving as the primary equipment for reducing the size of ore particles It provides an overview of the latest advancements in mining mill technology, Ball mills as well as rod mills are widely used in the mining industry on account of their simplicity Ball mills in particular play an important role in secondary grinding of ores to final particle sizes smaller than 100 µm The market leader Metso Trends in der Minenindustrie Mineral Processing